Understanding Hydraulic Breaker Piston: Key Component in Demolition Equipment

Hydraulic breaker piston is a crucial part in the operation of hydraulic breakers. Hydraulic breakers are widely used in construction, mining, and demolition industries. The piston plays a central role in converting hydraulic energy into mechanical force for effective breaking. It is like the heart of the hydraulic breaker, pumping life into the equipment to perform its intended function.

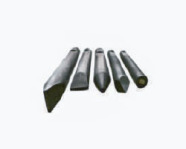

Design and Construction of Hydraulic Breaker Piston

The design of the hydraulic breaker piston is a complex engineering task. It needs to be precisely engineered to withstand high pressures. The piston is typically made of high-strength materials such as hardened steel. Its shape and dimensions are carefully calculated to ensure optimal performance. The surface finish of the piston is also important as it affects the sealing and the smooth movement within the breaker. The piston often has grooves or channels for proper lubrication and to manage the flow of hydraulic fluid.

Functioning of the Hydraulic Breaker Piston

When the hydraulic fluid is pumped into the hydraulic breaker, the piston starts to move. The high-pressure hydraulic fluid forces the piston to reciprocate rapidly. As the piston moves, it transfers the force to the chisel or tool attached to the breaker. This force is what enables the breaker to break through tough materials like concrete, rock, or asphalt. The frequency and amplitude of the piston's movement are key factors in determining the efficiency of the hydraulic breaker. A well-functioning piston can ensure a high-impact and continuous breaking action.

Maintenance and Durability of Hydraulic Breaker Piston

Maintaining the hydraulic breaker piston is essential for the long - term performance of the hydraulic breaker. Regular inspection for wear and tear is necessary. If the piston is damaged, it can lead to a decrease in the performance of the breaker. Replacing worn-out seals around the piston is crucial to prevent hydraulic fluid leakage. Also, proper lubrication of the piston helps in reducing friction and increasing its durability. High - quality pistons are designed to last for a long time, but they still require proper care and maintenance in harsh working environments.

News & Event